Asset Tracking Use Cases

Construction businesses have several use cases in common in terms of their equipment utilization and fleet management methods.

In this page you’ll learn how to leverage an equipment tracking system to solve the typical asset tracking use cases that apply to many contractors and improve efficiencies in your everyday handling of your construction equipment.

10 Common Construction Use Cases

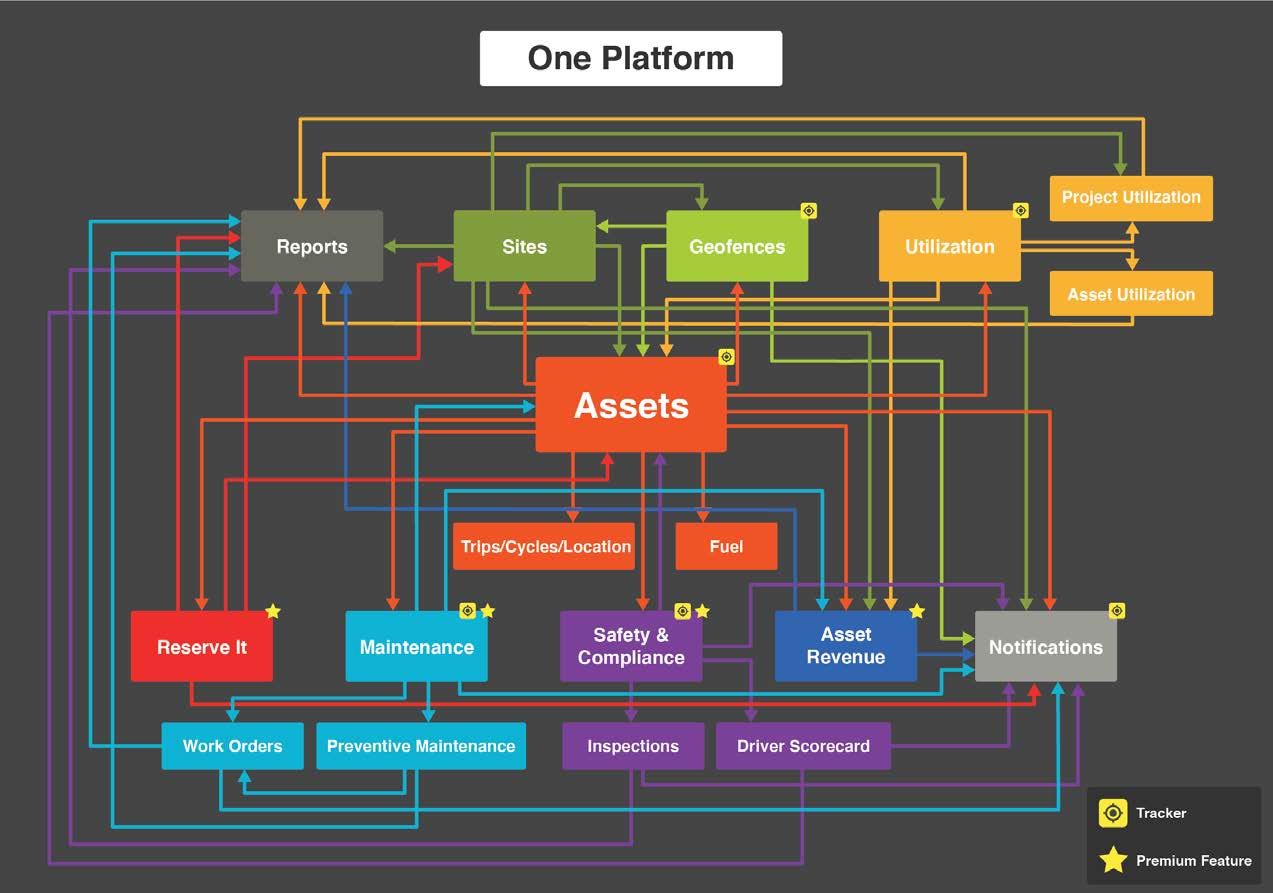

Equipment Tracking Systems offer 10 core solutions for common use cases among construction businesses to increase visibility, efficiencies and communication, reduce costs and alleviate key operational pain points.

Construction Equipment Management System Fundamentals

When shopping for an equipment management system for your construction assets, make sure you have your goals defined for each of your use cases first.

Equipment management software systems today come with many bells and whistles, which, while attractive, may not meet or connect with your true needs.

But how do you know what to look for when researching a system that supports your construction use cases?

We are here to cover the fundamentals of a construction equipment management system based on typical construction use cases, so you can align your needs with what is available and are clear on how to leverage the solution you choose to meet your goals.

Fundamental Construction Use Cases

An equipment management solution that is best for a contractor like you should naturally solve for a contractor’s typical use cases at its basic level, or as additional optional functionality based on your needs and priorities.

Since we come from construction, in this article we summarized the top 10 typical equipment-related use cases we and our peers have experienced. Look for the features and functionalities indicated in each of the following use cases when shopping for a solution for each use case.

1. Asset Database Knowing What You Have

Instead of your filing cabinet, multiple whiteboards at your projects sites and shop, or standalone computer drives, a digital asset database is your single source of truth for what is currently in your fleet. An asset management system can be leveraged as a cloud-based database for all asset records.

In addition to basic asset data points and records (including make/model, purchase information, insurance, etc.) digitizing your asset database in an equipment management system automates data updates like engine hours or miles, and maintenance records that would otherwise need to be done manually on paper and logged later. A well organized and easy-to-use database is at the root of any effective equipment management system.

Features and functionality to look for:

- Asset Database (library of asset data and details)

- Tracker Management (maintaining tracker health and connection)

- Utilization Monitoring (engine run time)

2. Location Tracking Knowing Where Everything Is

As this goes along with knowing what you have, most companies struggle to know where their stuff is. An equipment management system that is best for construction can track all of the types of assets in a construction fleet from heavy equipment to mid-sized assets and machines, to heavy trucks and vehicles, to small tools, materials, parts and attachments.

It must include hardware that can pull data specific to that asset type and send it to your equipment management platform to interpret in ways that are meaningful and relevant to construction businesses. Mobile apps help maintain this visibility on and offsite.

Its beneficial and most efficient for contractors to track all of their construction related assets on a single system vs. multiple separate, redundant systems and is better for cost control and total visibility.

Features and functionality to look for:

3. Overall Equipment and Field Management

In addition to knowing where your stuff is, you also need to coordinate and communicate equipment use across operations and teams. An equipment management system best for construction provides total visibility across all of your construction operations. That includes projects as well as your shops, yards, offices and anywhere across the map that your assets may travel to.

Among its many features that interpret data about your equipment, an effective management system works for your entire team from your owners and executives, to your equipment manager, to your project managers and supers to your crews in the field. The system should provide notifications for appropriate visibility based on user roles and permissions and offer timely alerts for improved response times to urgent needs. It should consolidate analytics and data to easily report on insights that can be applied to improve operations and decisions.

Features and functionality to look for:

- Reports (customizable)

- Notifications (multiple methods and configurations)

- Reservation and Scheduling tools

- Sites (Projects, Offices and Yard site location identification)

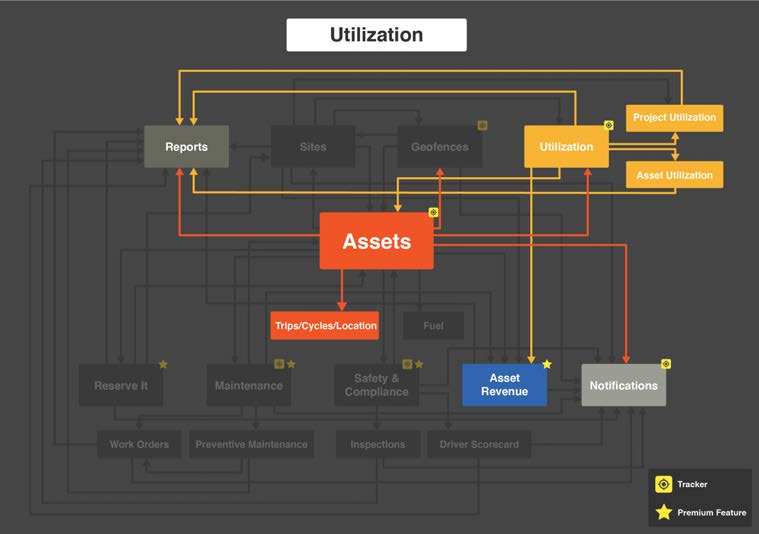

4. Asset and Project Utilization

One key to effective equipment management is knowing how your machines are utilized. An equipment management system that is best for construction should pull telematics data from your asset’s engine to help the contractor understand how each vehicle or piece of equipment has been used over time. It should allow you to customize thresholds that help visualize when your assets are under utilized based on metrics that are specific to the size of your fleet and your current workload.

These insights can help a contractor benchmark what their forecasted or expected utilization should be based on previous data and indicates when those forecasts are missed or exceeded. This can also help shape accurate billing rates.

Features and functionality to look for:

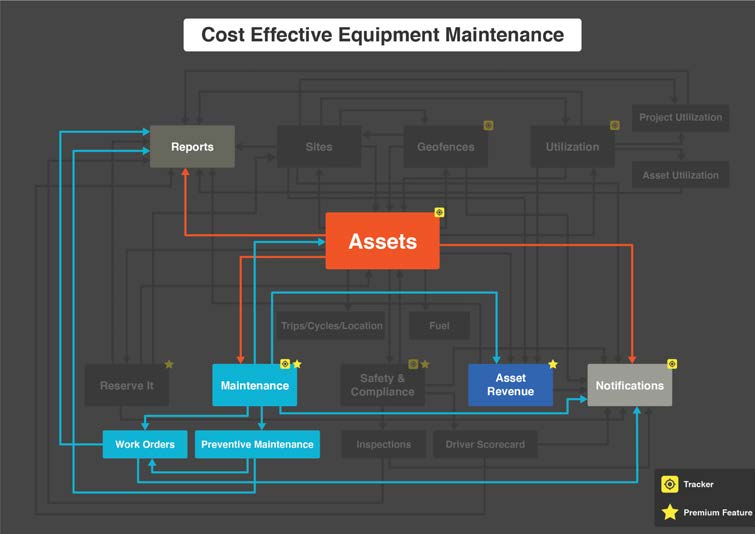

5. Cost Effective Equipment Maintenance

One of the most frustrating things to happen in the field is when equipment breaks down and delays productivity. There is just no reason for it. Equipment is required to stay in safe and working condition to support a construction business’ operations. An equipment management system best for construction includes scheduling of recurring preventive maintenance with customized thresholds, triggers and indicators and specified services that fit into your business’ existing maintenance routines. It should also include mobile accessibility with voice memos and on-the-go submission capabilities for ease and efficiency.

This feature optimizes work for mechanics and improves communication between the shop and the field to keep assets up and running and keep projects outfitted with the resources they need when they need them. It also ensures that assets are kept in tip-top shape to extend their lifespan and reduce owning and operating costs.

Features and functionality to look for:

- Preventive Maintenance (with custom recurrences and automated triggers)

- Service Requests and Maintenance Entries (track maintenance activities)

- Work Orders (maintenance services and repairs for each asset)

- Asset Revenue (monitoring maintenance costs in relation other asset costs)

- Customization

- Mobile App

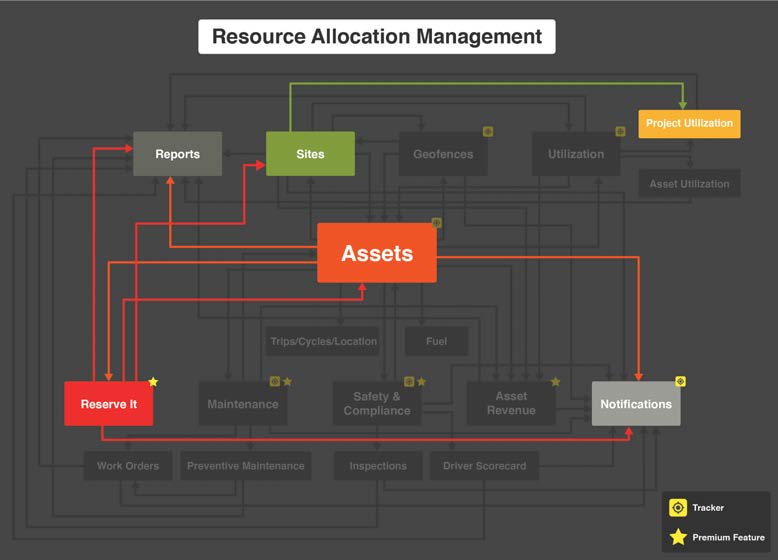

6. Requests and Reservations Resource Allocation Management

Often times job sites wrestle over who needs the equipment more and for how long, hoard assets on their sites that they don’t currently need or conflict with preventive maintenance needs. Because physical assets are required to complete work, an equipment management system that is best for construction should provide a mechanism for teams to request and reserve assets that they need to support their scopes.

Request and reservation tools help field teams schedule their asset needs and share resources across sites, and help shop teams coordinate critical maintenance or repair activities with project needs.

Features and functionality to look for:

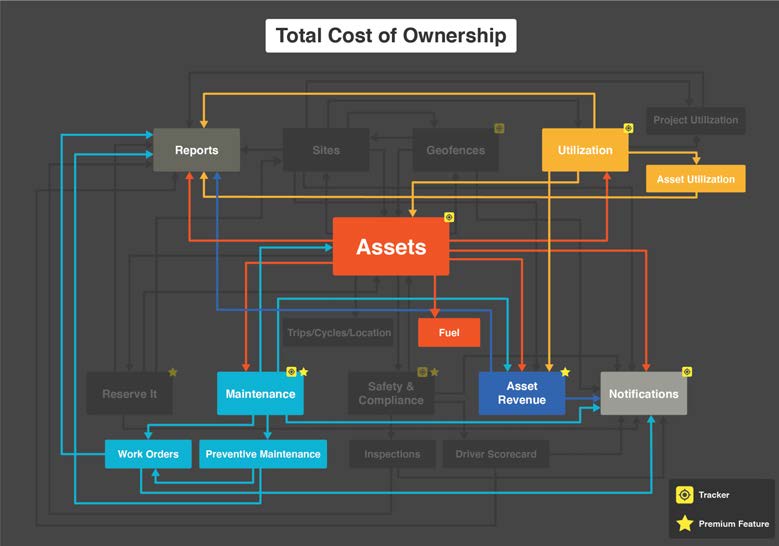

7. Total Cost of Ownership

Contractors want to know how much it’s costing them to own and operate their equipment. Construction is an asset intensive business and equipment is one of their biggest investments and cost centers. Between initial investment costs, over or under utilization, maintenance and repair costs, revenue generated from the use and rentals of assets, and depreciation, contractors want data that gives them the ability to easily draw conclusions on how much their assets are costing them.

Knowing this information gives insights that better inform on when it makes better sense to own vs. rent and know when it’s time to unload an asset that is costing more than its working for the business.

Features and functionality to look for:

- Maintenance Scheduling and Tracking

- Utilization Monitoring (engine run time)

- Asset Revenue (monitoring maintenance costs in relation other asset cost)

- Financial reports

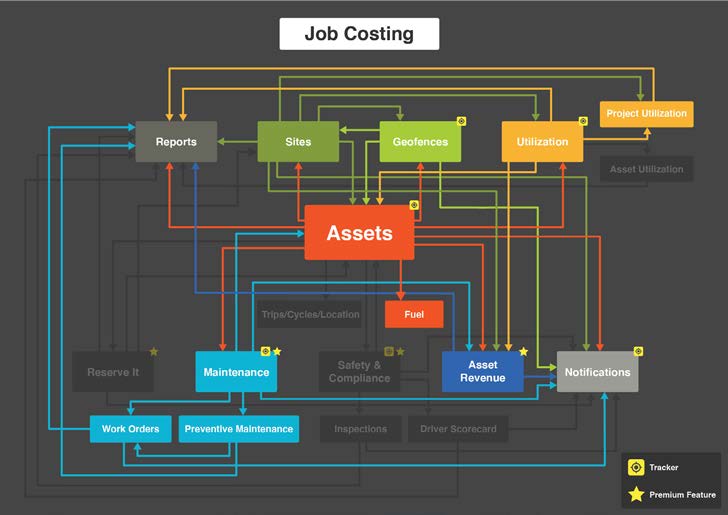

8. Job Costing Knowing and Controlling Project Costs

A major part of operating a successful construction business is controlling costs at the job level to maximize margins and overall profits. In addition to labor, contractors need to track equipment costs for each job, including billing rates, external rental revenue, external rental costs, purchasing costs, repairs and service costs, and more.

An equipment management system should be able to accurately capture and deliver these costs for each project based on site activity, automations, calculations, and accurate record keeping.

Features and functionality to look for:

- Sites and Geofences (tracking and automating data on assets within projects)

- Asset Revenue (billings and rental revenue)

- Utilization Monitoring (engine run time)

- Parts and Labor (costs for maintenance activities)

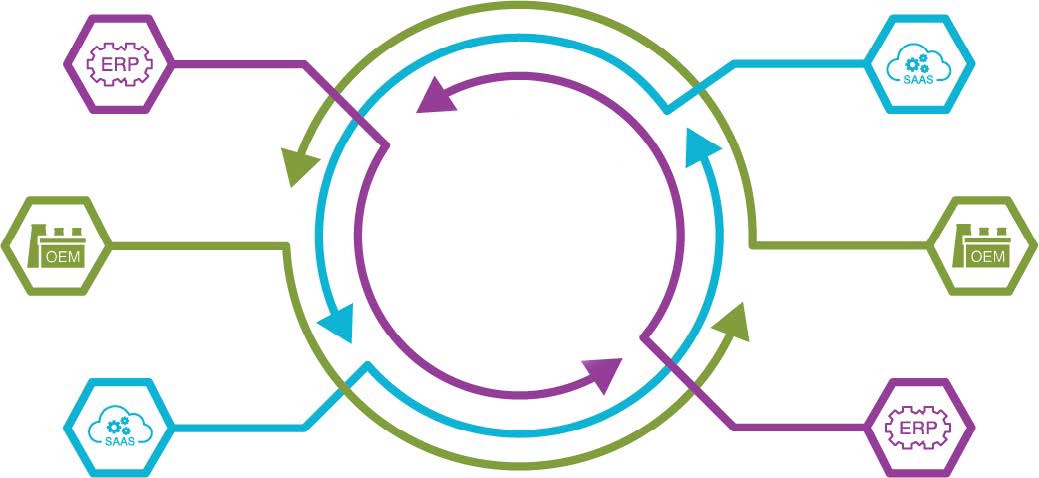

Contractors often already use construction software in other areas of their business, such as accounting, estimating and scheduling. The best equipment management solution should be able to talk to other software systems to share data and optimally support all areas of the business. In addition, contractors may have OEM telematic systems ties into equipment manufactured by Komatsu, John Deere or Caterpillar.

Having multiple systems can conflict with their effort to consolidate data for all their assets into a single equipment management platform. By using an equipment management system that can integrate with these manufacturers’ systems, they can incorporate and co-mingle this third-party data with the rest of their assets to gain visibility and comprehensive data about their entire fleet on a single platform.

Features and functionality to look for:

- Utilization Monitoring (engine run time)

- Sites and Geofences (tracking and automating data on assets within projects)

- Asset Revenue (billings and rental revenue)

- Reservation and Scheduling tools

- System Integrations

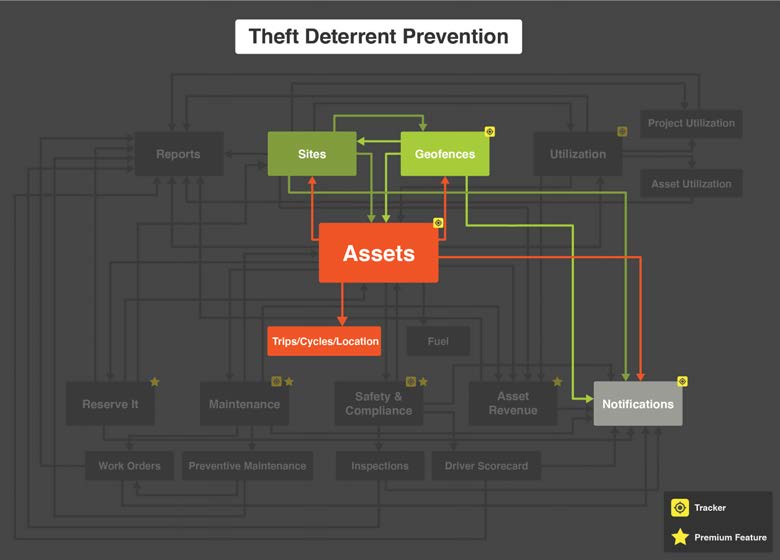

10. Theft Prevention

Contractors can lose up to 10% of their fleet each year due to internal theft. Much of this loss does not get recovered. An optimal equipment management system that is best for construction allows contractors to trace automated geofences around their site locations to monitor for asset entry and exit events. Configuring notifications during specific time frames helps identify potential instances of theft when equipment is moving during unauthorized hours.

This visibility aids contractors in their overall equipment, field and project management and helps reinforce asset location and movement activity. It also gives owners the confidence that equipment is always accounted for, and their investments in their expensive mixed fleet assets are protected.

Features and functionality to look for:

Conclusion

When you are looking for solutions for your specific needs, you can leverage a technology system to generate the data you need to bring you closer to achieving your goals and benefit from the value that these systems offer your business.

Construction equipment management systems built for contractors include features and functionality designed to fulfill these unique use cases. Identifying the appropriate solutions up front will help you feel confident that you are partnering with the best system and provider for your needs.

Construction businesses lose up to 10% of their inventory each year. With mixed assets spread across multiple project sites, its easy for assets to get left behind.

Construction equipment platforms help you manage everything from heavy equipment to handheld tools.

Skip the complicated, manual data entry with a variety of automated trackers, a simple mobile app and an intuitive web interface you can use from anywhere.

Asset Library

Sites and Groups

Trackers

Equipment Management Solution

Do you struggle to see and manage your mixed assets across your operations? Construction technology platforms are designed to let you Know More, Control More and Make More so you can stay connected to your assets, maximize your operations and resources and grow your business.

An equipment management solution will simplify your equipment fleet management from the field to the shop to the office and anywhere in between. View your assets in an organized asset library, study asset and site utilization and manage requests between job sites seamlessly, keeping your team connected.

Asset Library

Utilization

Sites and Geofences

Features and functionality to look for: