Equipment Utilization Tracking

Understand Your Equipment Utilization

One key to effective equipment management is knowing your equipment utilization. We understand the importance of these metrics and built an equipment management system using advanced hardware that pulls telematics data from your assets’ engines to help you understand the utilization of your machines and vehicles over time on one platform.

Tenna’s Asset and Project Utilization functionalities provide accurate and reliable data from your assets and monitor your equipment utilization. You can evaluate trends over time by measuring how often your assets are working (or not working), reviewing equipment utilization reports by asset and project, and make more informed decisions about owning, renting or selling your assets.

Equipment Utilization Features and Functionality

Tenna allows you to define your utilization benchmarks and customize thresholds to easily visualize when your assets are underutilized based on metrics that are specific to the size of your fleet and your current workload.

View data on assets used collectively on projects, as well as individual asset utilization to benefit the Operations teams, Cost Accountants, Equipment Managers and Estimators.

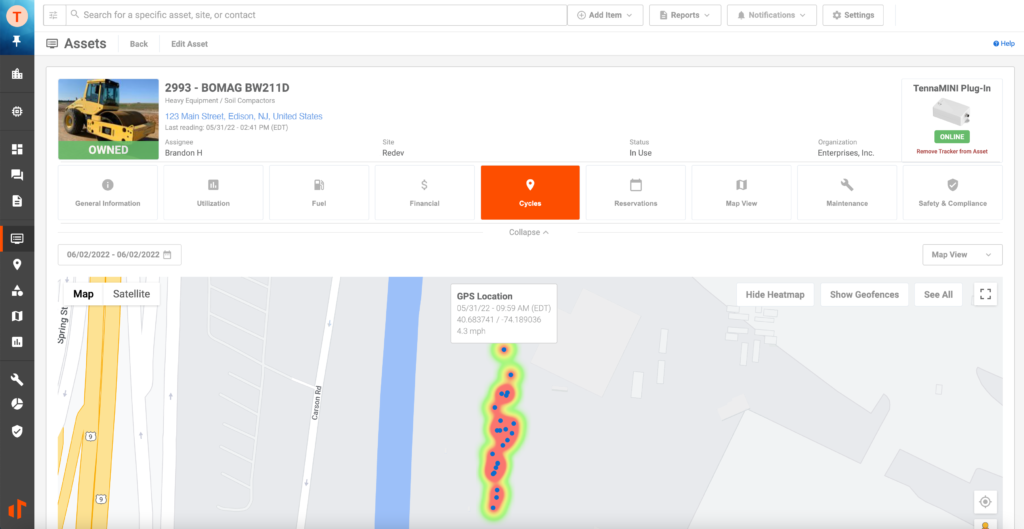

Integrated Equipment Tracking Devices

Hardwire your gps asset trackers into your engine operated assets to monitor run time in the form of hours or miles.

Analytics

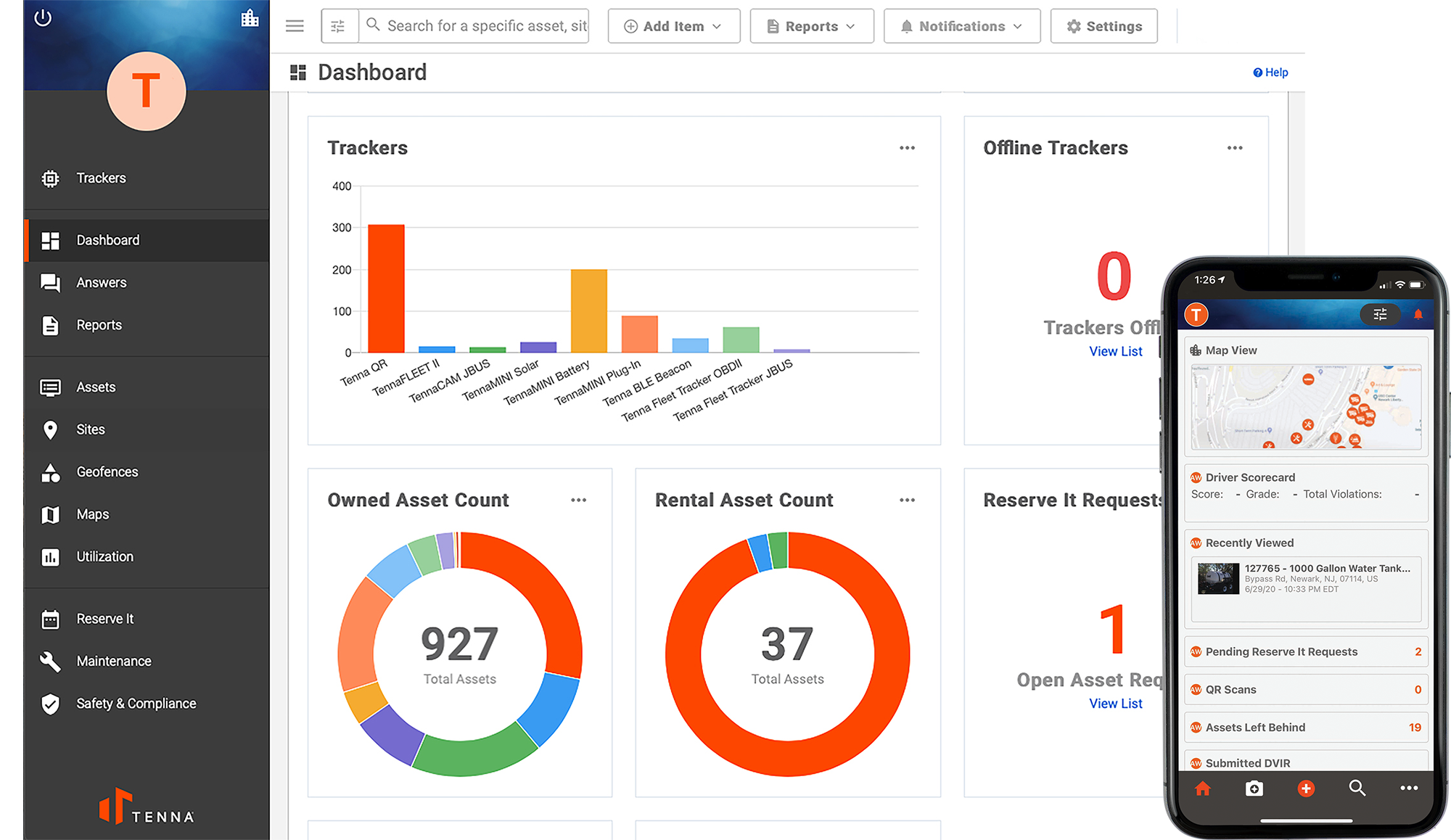

Our analytics tools give you an easy way to quickly look up and extract equipment utilization data on your performance and records, get immediate insights and actionable intelligence.

Dashboards provide a high-level view of assets for optimal fleet management. See when an asset is being underutilized so you can stay on top of assets you no longer need.

Reports let you quickly look up and extract relevant equipment utilization data. Sort and filter to view utilization for specific equipment category types or models.

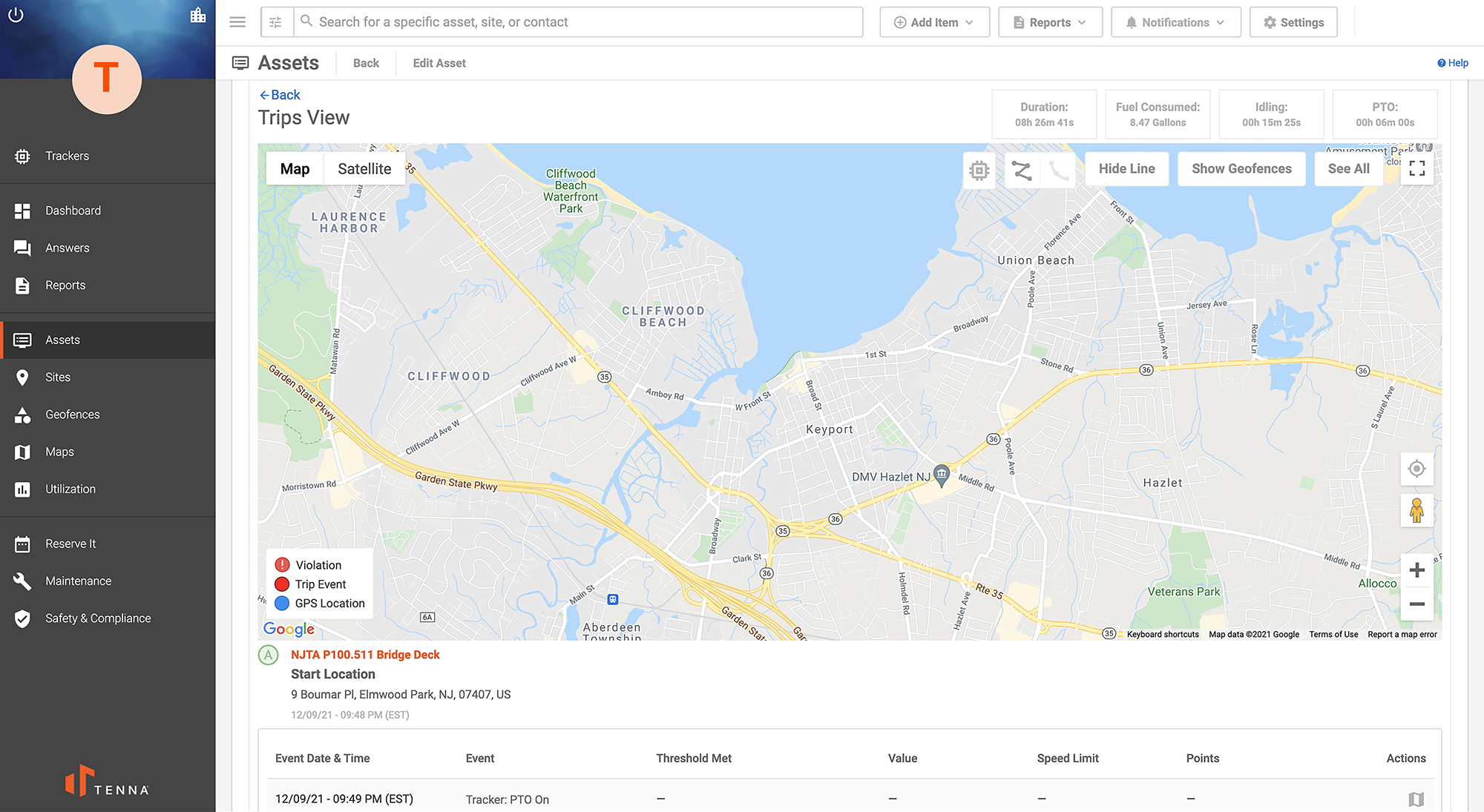

Power Take Off (PTO)

Capture when the engine is being used for an activity other than running the asset. View PTO status live across maps, see Trip or Cycle Events for PTO Engaged and total PTO duration, and see PTO column in existing Trips or Cycle Reports.

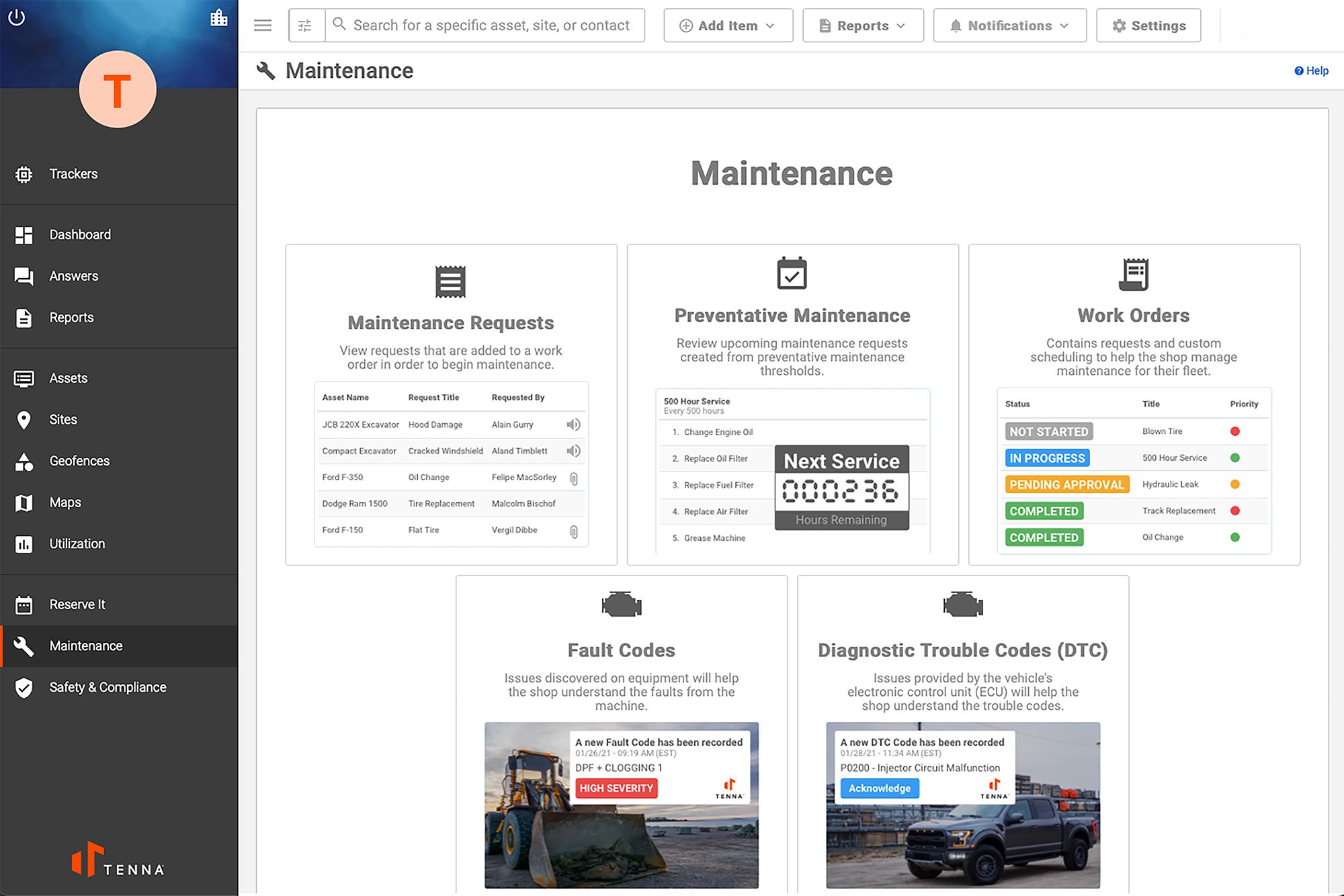

Maintenance

Automate your equipment maintenance activities and needs based on pre-configured asset usage triggers. Stay proactive and ahead with maintenance alerts and reminders.

Integrations

Integrate with third party OEMs to get AEMP and other heavy equipment telematics data including utilization from other manufacturers that are a part of your construction fleet.

Tracker Management

Monitor your equipment trackers and see their status to maintain tracker health and connection so accurate equipment utilization data continues to flow to the platform uninterrupted.

"[The data] really helps us make decisions about where to allocate our resources on what projects based on how they're being utilized."

Jake J., Director of Operations, R.J. Grondin & Sons

Benefits of Equipment Management Systems for Equipment Utilization

Better Business

- Accurate cost and utilization data helps to develop solid bid rates, improve competitiveness and keep winning work

- Increase cost earnings and savings

- Reduce your total cost of ownership

- Improve forecasting and billing

- Improve decision making

- Improve record keeping

Increased Efficiencies and Productivity

- Improve equipment management with increased visibility, productivity and utilization

- Improve communication

Equipment Utilization Overview

Learn more on How to Maximize Equipment Utilization.

Want to See Tenna in Action?

Schedule a Demo