Edison, NJ — July 20, 2023 — TENNA, the construction technology platform that revolutionizes equipment fleet operations, announces the release of a new hardware product for heavy equipment that also allows for tracking third-party powered accessories. Tenna also announces the release of a new premium add-on product: Custom Inspections.

Tenna’s new TennaCANbus tracker is an updated way to track heavy equipment. By installing the TennaCANbus on heavy equipment, users can now track and monitor idle time, fuel consumption, asset information, engine information, battery level, fault codes & decoded messages, environmental data, and tracker analytics—in addition to the location, utilization, and maintenance data previously collected.

CAN (Controller Area Network) or CAN bus is a widely used communication protocol that allows different electronic control units (ECUs) within a vehicle or piece of equipment to communicate with each other. It is a network protocol that helps data exchange between various systems—such as the engine, transmission, brakes, sensors, and more. CAN bus enables real-time, reliable, and robust communication, making it suitable for applications requiring extensive data coverage and integration between different machine components.

TennaCANbus enables construction equipment managers to make better decisions about rentals, replacements, preventative maintenance, and resource management. The tracker also makes it possible to track external power take-off (PTO), which enables the use of an asset’s engine power to drive added equipment or perform specific tasks. External PTO is often used to provide power to external accessories, including hydraulic pumps, generators, winches, compressors, and other types of equipment that require mechanical or electrical power to operate.

“This is an evolutionary step for us to have hardware that can get even more data off of a machine,” says Jose Cueva, co-founder, and vice president of product at Tenna. “It also captures any factory installed or after-market PTO, making it a comprehensive device for a wide array of data that can inform better field decisions, maintenance planning, and resource management.”

TennaCANbus is poised to be a game-changer for construction companies trying to achieve greater productivity, efficiency, and business growth. Maintenance, diagnostic troubleshooting, and service planning are made easier with additional information on runtime and frequency of PTO engagement. Fuel use and idling metrics give a more comprehensive picture of where waste and excessive wear and tear are occurring. Understanding more about how heavy equipment is being used, including when PTO is engaged, can simplify reporting around compliance with safety regulations and improve billing by making the distribution of costs more accurate.

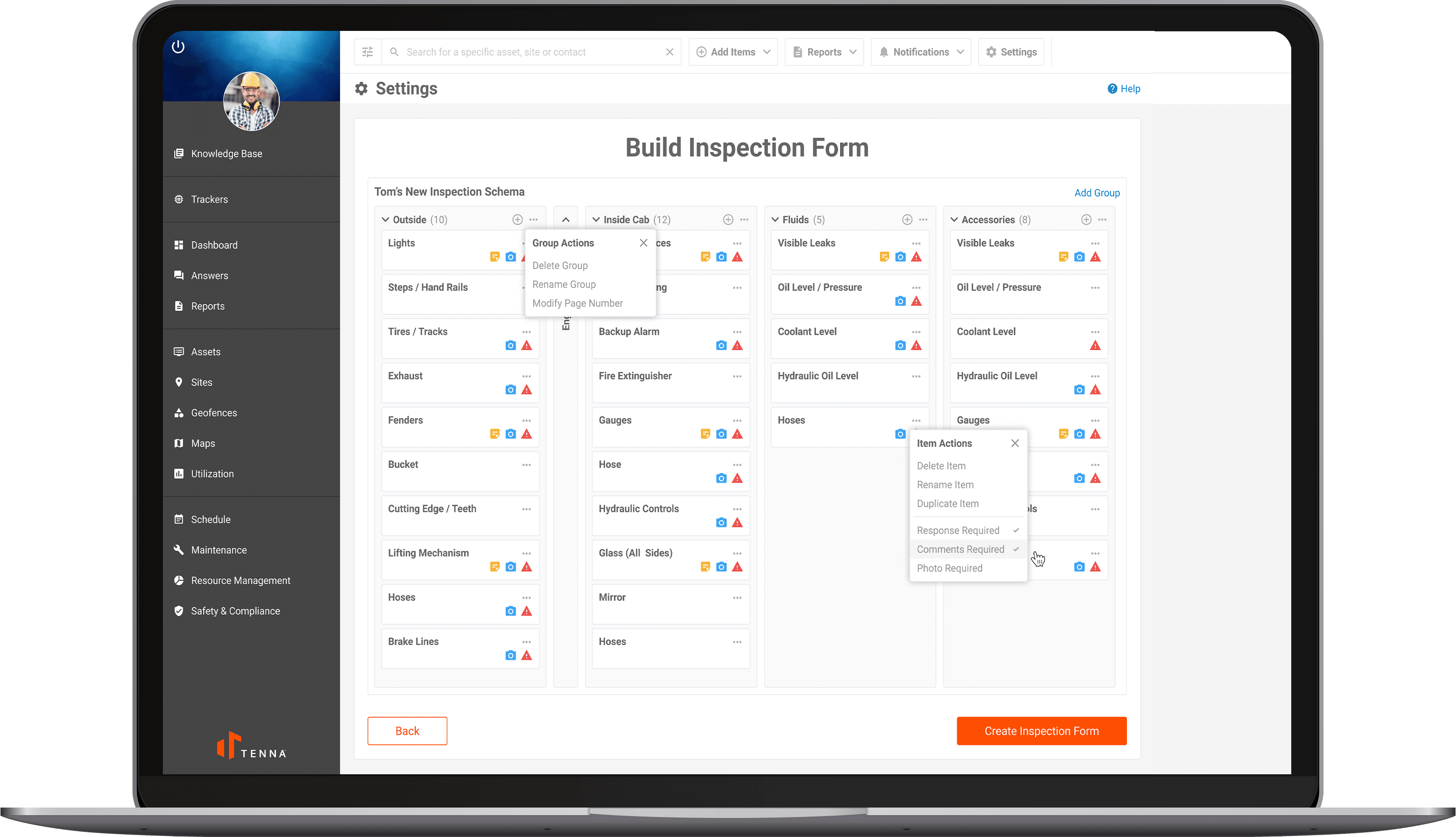

Tenna’s new Custom Inspections is a premium add-on to the Safety & Compliance license, which lets project, safety, and administrative personnel manage and monitor safety and compliance across an entire equipment fleet. Tenna’s digital inspections replace paper-based methods, making it easier and more efficient and resulting in a higher likelihood of inspection completion. The new Custom Inspections add-on allows users to create inspections specific to job sites, use cases, or types of equipment, mandate custom fields and signatures, and instantly apply new forms to all applicable assets.

According to Cueva, “Custom inspections are an excellent way to tailor inspections to unique use cases. If a certain type of asset is prone to leaks, you can add custom fields to an existing inspection form to check for that. If assets on a particular job site seem more prone to external damage, you can create new forms for anything allocated to that site. Inspections become more useful and more meaningful.”

With the launch of these new products—as well as ongoing enhancements to existing features—Tenna continues to demonstrate its commitment to helping construction companies grow and succeed while improving safety and productivity.

Contact Tenna to learn more about adding TennaCANbus and Custom Inspections to your construction business.

About Tenna

Backed by over 100 years of experience in the construction industry, Tenna was built to revolutionize construction equipment and fleet operations. Tenna is the only equipment management system built exclusively for the construction industry and tailored to solve the specific challenges it faces with GPS-based locations and actionable data and reporting. From heavy iron; to vehicles and mid-sized equipment; to attachments, small tools and consumables, Tenna provides a complete view of entire construction equipment fleets on one platform that also integrates with a variety of business ERPs and project management systems. In the field, Tenna users gain more control over equipment utilization, master job costing, and better oversight over safety and compliance needs. At the office, Tenna users have full visibility over and improved communication with the field, shop, and between departments. The result is the power to make informed decisions, gain more business, and complete jobs more productively and profitably. For more information, visit https://www.tenna.com.

Join the discussion on the Tenna Blog and connect with Tenna on LinkedIn, Facebook, Instagram and YouTube.