7 Best Construction Equipment Maintenance Software [2025]

- Jason Mercury

- February 12, 2025

There are plenty of tools out there that can help you track maintenance requests, but only a few are purpose built for construction equipment and construction shops and field mechanics. Construction businesses will benefit most from software that:

- Automates maintenance scheduling to avoid missing critical service, reduce human error and prevent unexpected breakdowns

- Provides real-time equipment health monitoring for data-driven maintenance decisions

- Keeps a digitized, live library of parts for inventory management and smoother maintenance requests, work orders, and emergency repairs

- Tracks mechanic time to keep tabs on not only resource needs but also the true cost of equipment repairs and maintenance

- Connects directly to equipment inspections for safety and immediate attention to equipment repair and servicing needs.

- Centralizes record-keeping for regulatory compliance and equipment reliability tracking

- Offers comprehensive reporting with insights into equipment performance and maintenance history

- Includes mobile access for field teams to update and retrieve information quickly

- Integrates with construction ERPs to centralize cost data.

Tenna works with over 500 construction companies, and we’ve built and evolved our maintenance offering to cater to exactly what contractors need to simplify their construction maintenance operations.

In this guide, we’ve compiled the best construction equipment maintenance software platforms. We’ll compare their advantages, shortcomings, key equipment maintenance features, and pricing.

The first on the list is our own solution, Tenna. It’s designed by contractors for contractors to easily manage the scheduling and tracking of all elements of vehicle and heavy equipment maintenance.

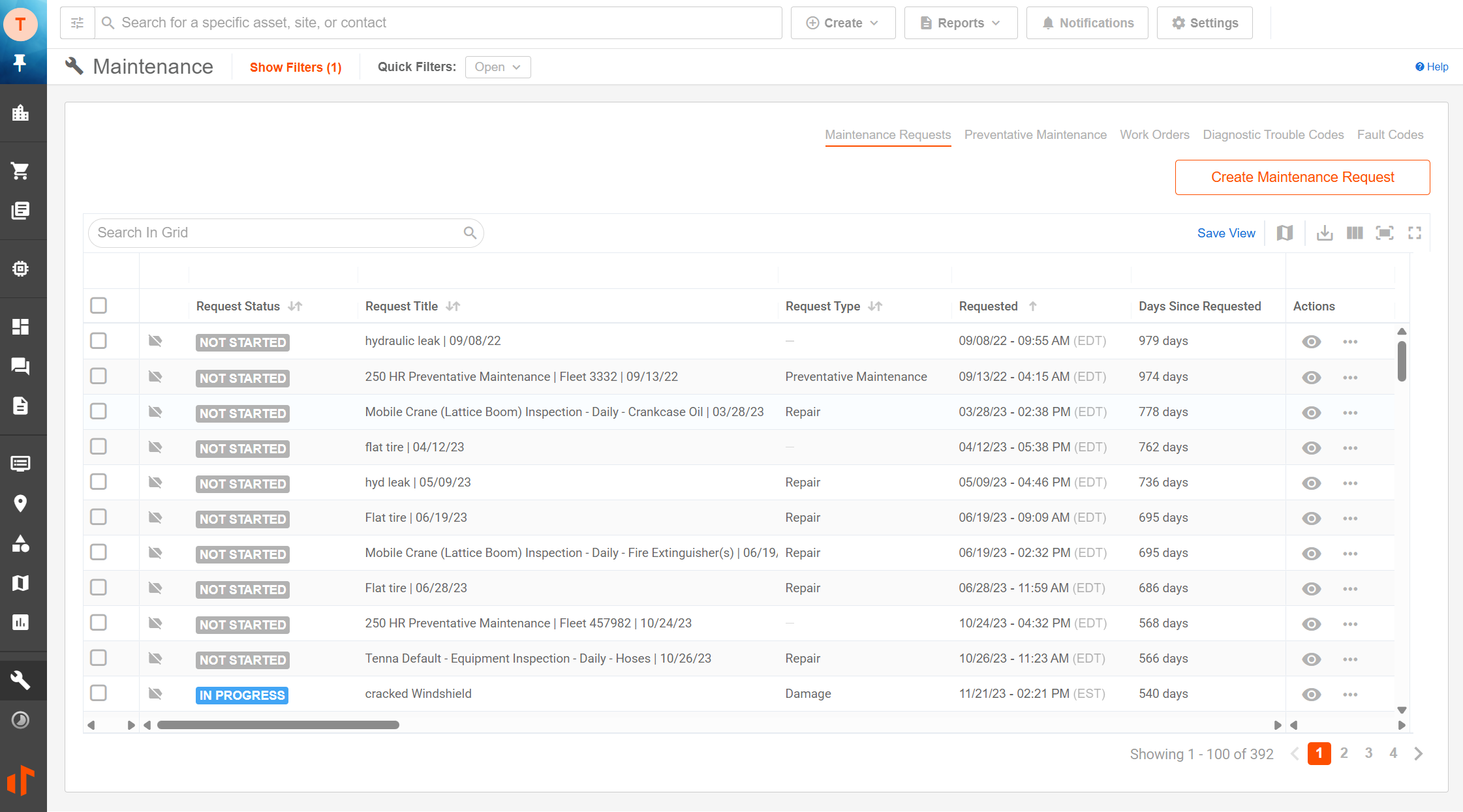

1. Tenna

Tenna is a complete construction technology platform designed to help contractors maximize mixed fleets with solutions that connect field, shop, and office. Our computerized maintenance management system (CMMS) handles everything from preventative maintenance schedules to mechanic workloads, helping you extend equipment lifespan and increase equipment uptime.

Maintenance Requests

When you use our CMMS software, there’s no need for field teams to leave the jobsite to report equipment problems. Workers submit maintenance tasks through the Tenna mobile app using voice memos or text notes, while managers can track request status with detailed asset-level data to prioritize workloads.

Preventative Maintenance

Skip the one-size-fits-all approach and set the right maintenance schedule for each piece of fleet equipment. Create schedules based on equipment usage, including hours, miles, or calendar days. When preventive maintenance tasks are due, Tenna automatically creates maintenance requests, helping you avoid missing critical service intervals even during busy project periods.

Fault Codes and Diagnostic Trouble Codes (DTC)

Know exactly what’s wrong with your equipment before sending a mechanic. GPS trackers send equipment fault codes directly to Tenna, speeding up response times and converting fault codes to maintenance requests with one click.

The diagnostic trouble code feature pulls information directly from your vehicle’s electronic control unit, helping shop teams understand root causes rather than just symptoms.

Parts Management

Stop wasting time hunting for parts across multiple locations or facilities. The built-in parts catalog and inventory tracking shows what’s available where. Request parts through the app, track lifecycles and warranties, and prevent inventory shortages that delay repairs.

The system alerts you when parts reach minimum quantities and tracks fulfillment status, helping you avoid scheduling delays without overstocking inventory.

Time Cards

Spend mechanics’ time wisely — on the right jobs and costs. With Tenna, mechanics log time against sites, assets, work orders, and specific maintenance requests. Make them work for your team by customizing time types and class codes and setting labor cost rates. Then, incorporate your approval process for more efficient time card reviews.

Cost Codes

Tenna’s cost codes are fully customizable, giving you complete visibility into equipment maintenance expenses. Associate cost codes with preventative maintenance, work orders, mechanic time cards, and more. This helps with accurate job costing, identifying problematic assets, and getting a complete understanding of your finances.

Repair Documentation and Reporting

Effective maintenance of your construction equipment does more than just reduce idle time and keep equipment running — it impacts your bottom line. Tenna helps you control operating costs by minimizing unexpected repairs and labor expenses and retain better compliance documentation and equipment records for regulatory requirements.

Tenna’s robust reporting includes:

- Parts consumption

- Maintenance records

- Failed mechanical inspection forms

- Rental cost reports

- And other performance reports

Customer Support

Tenna’s support starts with hands-on implementation and continues for the life of your account. When questions arise, you can speak directly with an expert or use our online help system with step-by-step guides and videos.

To set up your team for success, we also offer SOP consultations, specialized mechanic certification training, a dedicated account rep, and role-based training customized to each user’s specific needs.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation ✅

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ✅

- Automated Fault Codes/DTCs ✅

- Cost Codes ✅

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning ✅

- Field-to-Shop Maintenance Requests ✅

- Mechanic Time Cards ✅

- Mobile App ✅

- Natively Built into a Single Equipment Management Platform ✅

- Construction ERP Integrations ✅

- OEM/AEMP Integrations ✅

- Tailored to the Construction Industry ✅

What Real Customers Are Saying About Tenna

“We can now focus on being proactive with PMs and not reactive. Collecting hours daily gives our mechanics better insight into the health of our machines and allows them to create more realistic schedules. This, partnered with accurate locations of equipment has allowed us to better plan services and cut down on travel time.”

-Pat L., Project Manager, Severino Trucking

“We save money in preventive maintenance. So, we’re able to get things on time and down the road parts aren’t breaking down as fast.”

Mike B., General Superintendent, Zefiro

Pricing

2. Fleetio

Fleetio helps construction companies manage equipment maintenance by automatically scheduling services based on usage data. The software tracks maintenance across mixed fleets, which reduces equipment downtime, controls fuel costs, and stays compliant with regulations that affect construction operations.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation ✅

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ✅

- Automated Fault Codes/DTCs ✅

- Cost Codes ⚠️ (No Project/Job Codes)

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning ✅

- Field-to-Shop Maintenance Requests ✅

- Mechanic Time Cards ⚠️ (No Detailed Labor or Approvals)

- Mobile App ✅

- Natively Built into a Single Equipment Management Platform ✅

- Construction ERP Integrations 🚫

- OEM/AEMP Integrations 🚫

- Tailored to the Construction Industry ⚠️ (Designed for Multiple Industries)

Advantages

- Automated DTC and fault code collection from a wide range of telematics providers and OEM integrations

- Comprehensive parts and inventory management, including reorder notifications and usage tracking

Shortcomings

- Some users report that mechanic time tracking is basic and lacks granular labor breakdowns

- Inspection checklist customization is robust but advanced conditional logic is limited

Pricing

Starts at $4 per vehicle, per month (billed annually).

3. Limble CMMS

Limble CMMS offers maintenance software that keeps heavy machinery running reliably. The platform automates work order creation and tracking to maintain safer jobsites without added paperwork. It also helps schedule preventive maintenance to avoid equipment breakdowns and costly project delays.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation ✅

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ✅

- Automated Fault Codes/DTCs ⚠️ (via Select Integrations)

- Cost Codes ⚠️ (No Project/Job Codes)

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning ✅

- Field-to-Shop Maintenance Requests ⚠️ (No Voice Support)

- Mechanic Time Cards ✅

- Mobile App ✅

- Natively Built into a Single Equipment Management Platform ✅

- Construction ERP Integrations ✅

- OEM/AEMP Integrations 🚫

- Tailored to the Construction Industry ⚠️ (Designed for Multiple Industries)

Advantages

- Preventive maintenance automation with asset-specific schedules and escalation rules

- Integration with barcode and QR code scanning for parts and asset management

Shortcomings

- Automated DTC collection requires third-party telematics integration

- Cost code and project tracking is limited to general cost centers, not construction-specific codes

Pricing

Pricing not publicly available.

4. eMaint

eMaint’s construction equipment maintenance software helps contractors identify potential machine failures before they affect project schedules. The system tracks work orders, equipment, and materials while featuring condition monitoring tools that create maintenance tasks automatically.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation ✅

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ✅

- Automated Fault Codes/DTCs ⚠️ (via Select Integrations)

- Cost Codes ⚠️ (No Project/Job Codes)

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning ✅

- Field-to-Shop Maintenance Requests ⚠️ (No Voice Support)

- Mechanic Time Cards ✅

- Mobile App ✅

- Natively Built into a Single Equipment Management Platform 🚫

- Construction ERP Integrations ⚠️ (No Voice Support)

- OEM/AEMP Integrations 🚫

- Tailored to the Construction Industry ⚠️ (Requires Low Code Integration)

Advantages

- Extensive work order management system with multi-level approvals and automated assignment rules

- In-depth maintenance history and compliance tracking for audits and inspections

Shortcomings

- Construction is not a specific industry focus (they make solutions for manufacturing, facilities, oil & gas, food & beverage, healthcare, and government)

- Automated DTC collection works with select integrations and may not support all equipment types

- Mobile offline support can be inconsistent

Pricing

Starting at $69 per user per month (billed annually).

5. HCSS Equipment360

HCSS Equipment360 handles construction equipment maintenance through data-driven scheduling. The preventative maintenance scheduling system creates alerts based on calendar days, runtime hours, and odometer readings. It has additional tracking for equipment certification, licensing, inspections, and warranties.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation ✅

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ⚠️ (Basic Capabilities Only)

- Automated Fault Codes/DTCs ✅

- Cost Codes ✅

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning ✅

- Field-to-Shop Maintenance Requests ⚠️ (No Voice Support)

- Mechanic Time Cards ✅

- Mobile App ⚠️ (No Android Support)

- Natively Built into a Single Equipment Management Platform 🚫

- Construction ERP Integrations ✅

- OEM/AEMP Integrations ✅

- Tailored to the Construction Industry ✅

Advantages

- Native support for project and job cost codes is tied directly to maintenance activities

- Automated DTC and fault code collection from HCSS Telematics and OEM sources

Shortcomings

- Disjointed products are not all very well integrated into a single platform

- Mobile app is iPad-only, with no native Android support

- Inspection checklist lacks advanced conditional logic

- Pricing structure can quickly get expensive as you add more users

Pricing

Pricing not publicly available.

6. Simply Fleet

Simply Fleet construction equipment maintenance software helps teams execute service routines consistently. The software schedules maintenance based on equipment metrics like engine hours and mileage. It also sends automated alerts to ensure heavy machinery receives timely service to reduce project delays.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation ✅

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ✅

- Automated Fault Codes/DTCs ⚠️ (via Select Integrations)

- Cost Codes ⚠️ (No Project/Job Codes)

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning ✅

- Field-to-Shop Maintenance Requests ⚠️ (No Voice Support)

- Mechanic Time Cards ⚠️ (Basic Capabilities Only)

- Mobile App ✅

- Natively Built into a Single Equipment Management Platform ✅

- Construction ERP Integrations 🚫

- OEM/AEMP Integrations 🚫

- Tailored to the Construction Industry ⚠️ (Designed for Multiple Industries)

Advantages

- Automated maintenance reminders and scheduling based on odometer, hours, or time

- Digital inspection checklists with photo capture and custom fields

Shortcomings

- Cost code integration is limited to general expense categories, not project or job codes

- Automated DTC collection works with select telematics integrations only

Pricing

Starts at $20 per vehicle per year (billed annually).

7. EquipMate

EquipMate focuses on scheduled maintenance to prevent unexpected construction equipment failures. This software includes tools for planning equipment inspections and parts replacement, with alert functions that ensure maintenance tasks happen on time by tracking status, assigning work, and setting deadlines.

Key Equipment Maintenance Features

- Automated Maintenance Alerts ✅

- Preventative Maintenance Automation 🚫

- Work Order Creation & Assignment ✅

- Customizable Inspection Checklists ✅

- Automated Fault Codes/DTCs 🚫

- Cost Codes 🚫

- Equipment Parts Management ✅

- Parts Inventory Barcode Scanning 🚫

- Field-to-Shop Maintenance Requests⚠️ (No Voice Support)

- Mechanic Time Cards ⚠️ (Basic Capabilities Only)

- Mobile App ✅

- Natively Built into a Single Equipment Management Platform 🚫

- Construction ERP Integrations 🚫

- OEM/AEMP Integrations 🚫

- Tailored to the Construction Industry ⚠️ (Designed for Multiple Industries)

Advantages

- Has parts and service tracking with maintenance history logs for compliance

- Supports field maintenance requests with photo and note attachments

Shortcomings

- Lacks automated DTC collection, telematics integration, and cost code integrations

- Has mechanic time card tracking but lacks advanced approvals or multi-shift support

Pricing

Pricing not publicly available.

Ready to Keep Your Equipment Running Longer?

Tenna’s construction equipment maintenance system was built by contractors who understand what you actually need in the field and shop. Tenna’s platform connects everyone who touches equipment through a single system that tracks maintenance, from initial request to completion throughout the entire asset lifecycle.

Unlike basic maintenance logbooks or complicated enterprise software that wasn’t designed for construction, Tenna digitizes the entire maintenance process, from reporting issues from the field through a mobile app, to automatically scheduling preventative maintenance based on real usage, and helping you manage parts inventory so repairs aren’t delayed waiting for components.

Keep your fleet in top shape. Discover how Tenna’s construction-focused maintenance solution can help you streamline repairs, prevent breakdowns, and get the most out of your equipment.

About Jason Mercury

As Customer Success Enablement Manager with Tenna, Jason Mercury excels at bridging the gap that exists between customers and their success with new technologies. He thrives on helping partners recover revenue and create efficient business process with construction technology, and has been instrumental in driving customer and internal team training, leading to invaluable positive results across the board.

![7 Best Construction Equipment Maintenance Software [2025] - construction equipment maintenance software](https://www.tenna.com/wp-content/uploads/2025/11/unnamed-17.png)